LRPC STRANDS

Building a Better Tomorrow

What Does Low Relaxation Mean?

The low relaxation property is achieved through a technique referred to as "Stabilizing." This process includes a hot stretching method where the prestressing strand is subjected to a specific tension during the stress-relieving heat treatment. As a result, the steel experiences linear hardening, which greatly improves its resistance to creep and effectively reduces relaxation losses.

A low relaxation strand, when initially loaded to 70 percent of the specified minimum breaking strength of the strand, shall have relaxation losses of not more than 1.8 percent after 100 hours and not more than 2.5 percent after 1000 hours when tested under the controlled temperature of 20 degrees centigrade.

Project Highlights

State-of-the-art infrastructure and capabilities

European Technology

Brand new state of the art high tech inline pre-stressing machine from Europe

Fully Automated

European machineries to produce all variants of LRPC including compacted & indented LRPC

Galvanizing Line

Largest GAL Bed in India for heavy Zinc Coating to ensure corrosion protection

Plastic Extrusion

High-tech plastic extrusion line for coated LRPC with dedicated plastication line

Testing Laboratory

Fully equipped with latest state-of-the-art testing equipment and advanced relaxation test facilities

R&D Facility

In-house R&D facility and Technical Center for continuous innovation

Environmental Responsibility

Sustainability at the core of our operations

Solar Energy

Our plant is partially solar-powered, with plans to expand renewable usage

Carbon Footprint Reduction

Over 10,000 + trees planted through our transit house plantation program, with 11,000 more planned for this year

Zero Liquid Discharge

No wastewater is released, conserving vital water resources

Value Added LRPC Products

Comprehensive range of specialized LRPC strands

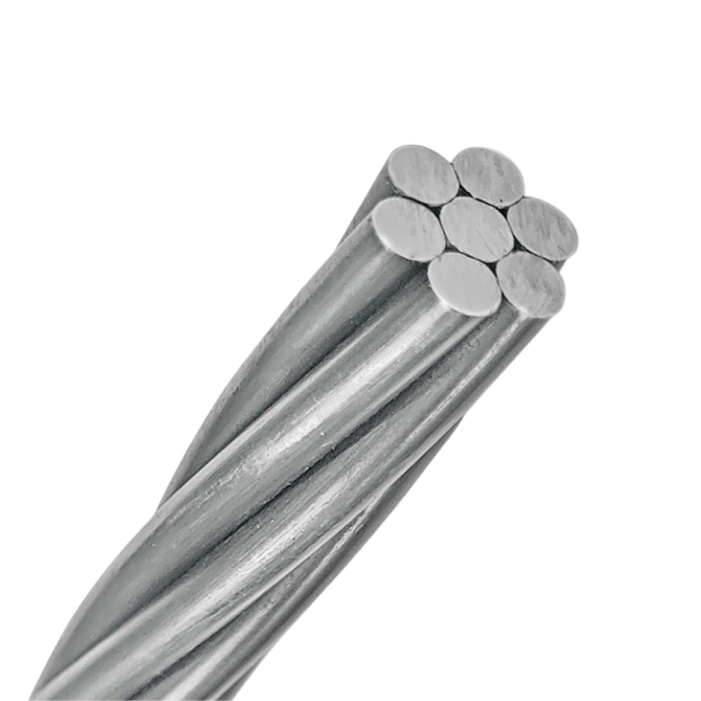

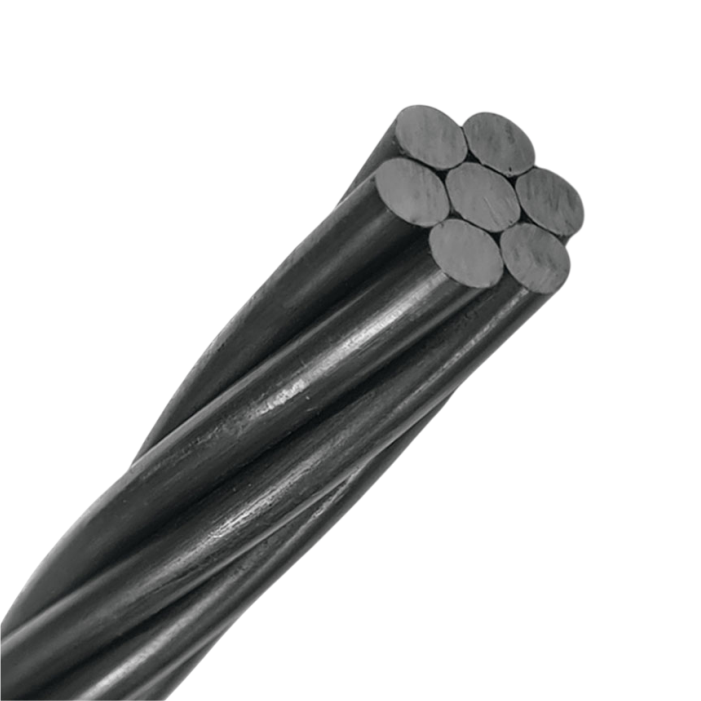

Galvanized LRPC Strand

Coated LRPC Strand

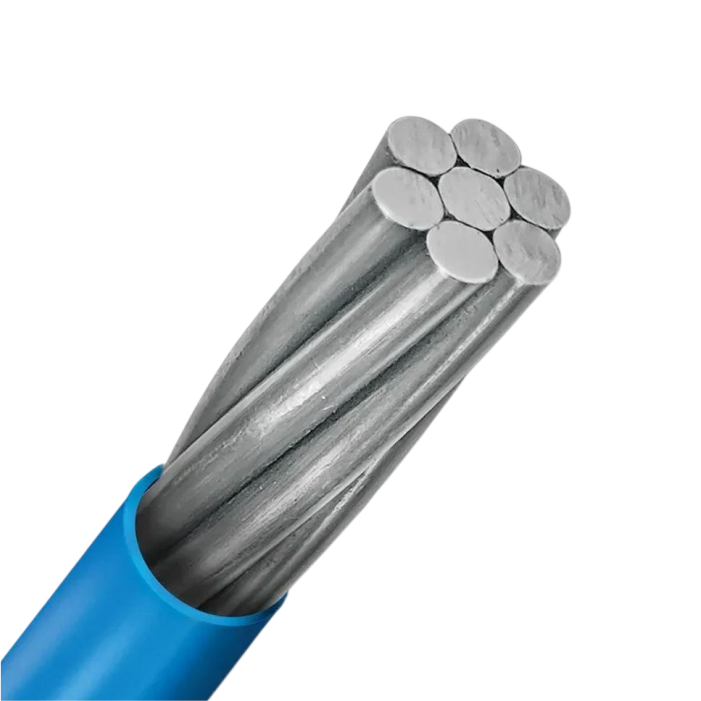

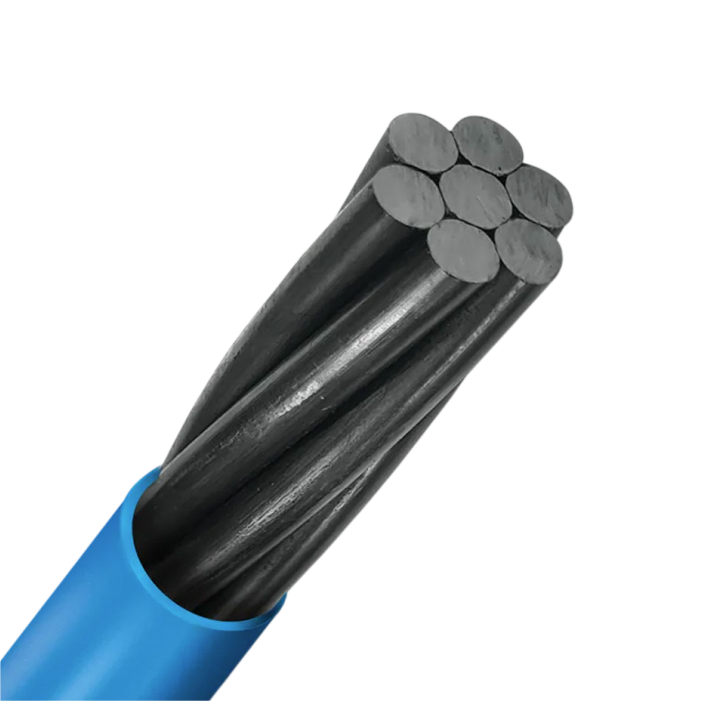

Polymer Coated Galvanized / Bright LRPC Strand

Polymer-Coated Grease/Wax-Filled LRPC Strands

Grease-Filled Unbonded PE Coated LRPC Strands

Indented LRPC Strand

*LRPC Strands of all available sizes and grades can be polymer sheathed and galvanized in conformance to all national and international specifications.

Advantages of Low Relaxation Strand

Up to 10% savings on construction costs due to reduced consumption of concrete and steel, alongside shorter lead times

Less stress loss at ambient and elevated temperatures

Uniform stress-strain relationship with higher breaking load and proof stress loads

Enhanced fatigue and corrosion resistance

Consistent physical properties achieved through uniform winding

Close tolerances maintained in the unit mass to length ratio

High reliability with on-site strand failure mitigated by online testing during manufacturing

Larger slab spans can be achieved with fewer columns

Facilitates the construction of stable and crack-resistant structures

Significantly reduces building weight compared to traditional concrete buildings, minimizing distortion

Enables the construction of strong, safe, and lighter structures with accelerated construction speed

Long-span cable-stayed bridges built without intermediate supports

Higher effective force in the tendon, due to lower relaxation losses. Saving in anchorages, ducts, sheaths, wedges

Extends the lifespan of cable-stayed bridges approximately 100 years

Minimizes environmental impact

Wide Applications Range

Providing structural strength, durability, and long-term stability for infrastructure projects

Cable Stay Bridges

High Speed Rail

Precast Construction

Flyovers & Interchanges

Wind Mills

Rock Anchoring

Metro Rail

Pre Fabricated Buildings

Large Concrete Infrastructure (Dams)

Manufacturing Line Features

Advanced and automatic pickling line, multi-block wire drawing and stranding

Built-in feature of supplying material on a tailor-made length basis to reduce wastage

Product Compliance

Meeting international quality standards

BIS & ISO 9001:2015

Indian Standards Certified

International Standards

BS5896 / EN1038 / ASTM / AS / NZS / JIS G 3536

Compliance Standards:

- Indian Standards: IS 14268 - 2017

- British Standards: BS5896 / EN1038

- European Standards: EN 10138

- American Standards: ASTM A416

- Australian and New Zealand Standards: AS/NZS 4672.1

- Japanese Standards: JIS G 3536:2014

In-House Testing Facility

Mechanical Properties Tests

- Fatigue property

- Relaxation property

- Angled breaking force (Deflected tensile)

- Cryogenic test

- Stress-corrosion test

- Breaking load test

Anti-Corrosion Filler Tests

- Congealing point

- Cone penetration

- Operating temperature range

- Oxidation stability

- Corrosion protection

- Compatibility with sheathing

- Dropping point

Engineering Polymer Tests

- Melt flow index

- Density

- Carbon black (Content/Dispersion/Distribution)

- Tensile strength (ambient & sub-zero temp)

- Thermal stability

- UV stability

- Environmental stress cracking resistance

Additional Tests

- Bond test

- Dynamic water tightness test

- Static water tightness test

- Impact test

Storage and Handling of Strands at Site

Proper care during storage and usage ensures optimal performance

Storage Guidelines

- Store strands in a dry, covered shed to prevent rusting and pitting

- For temporary outdoor storage, place coils on wooden support covered with waterproof sheet

- Never place coils on bare soil

- Ensure air circulation to avoid condensation on the coils

- Water soluble oil protects the strand during storage and can be easily washed away with water during use

Handling Guidelines

- Always protect strands from mechanical damage - abrasions, scrapes, or gouges can reduce breaking strength

- Use a well-made tight fitting strand payoff cage when pulling strands from inside coil

- Use spacers/wood blocks between strand coil and payoff cage to ensure tight fit

- Use cutting grinder to cut the strand after stressing

- Use good quality anchoring grips as strand is subjected to tensile and shearing stress

Important Precautions

- Welding and heating of prestressing materials must not be done

- Use disc cutters for cutting strands - flame cutters/torch not advisable

- Place strand pack so arrow pull direction faces the opening

- Ensure less than 2" space between strand pack and cage frame before cutting steel straps

- Caution: LRPC Strands are coiled under high tension - take adequate safety measures while uncoiling

Why Choose BWR

Industry Leader

Experienced steel wire rope manufacturer and largest exporter in India within this segment

Innovation Center

In-house R&D facility and Technical Center for continuous innovation

Strategic Location

Close proximity to Mumbai port, State & National highway

Advanced Technology

Fully automated European machineries for all variants of LRPC

Quality Assurance

Galvanized LRPC to ensure corrosion protection with largest GAL Bed in India

Environmental Commitment

Solar energy, zero liquid discharge, and 6,000+ trees planted

Ready to Build a Better Tomorrow?

Contact us to learn more about our LRPC Strands and how they can benefit your project