Crane applications of steel wire ropes

Steel wire ropes are

essential components of cranes that are utilized in various industrial

applications, including construction and manufacturing, material handling, and

shipyards. The proper functioning of these ropes is crucial for safety and

efficiency, as they are responsible for lifting and moving heavy loads. In this

blog, let’s explore the importance of steel wire ropes on cranes and the common

causes of failure.

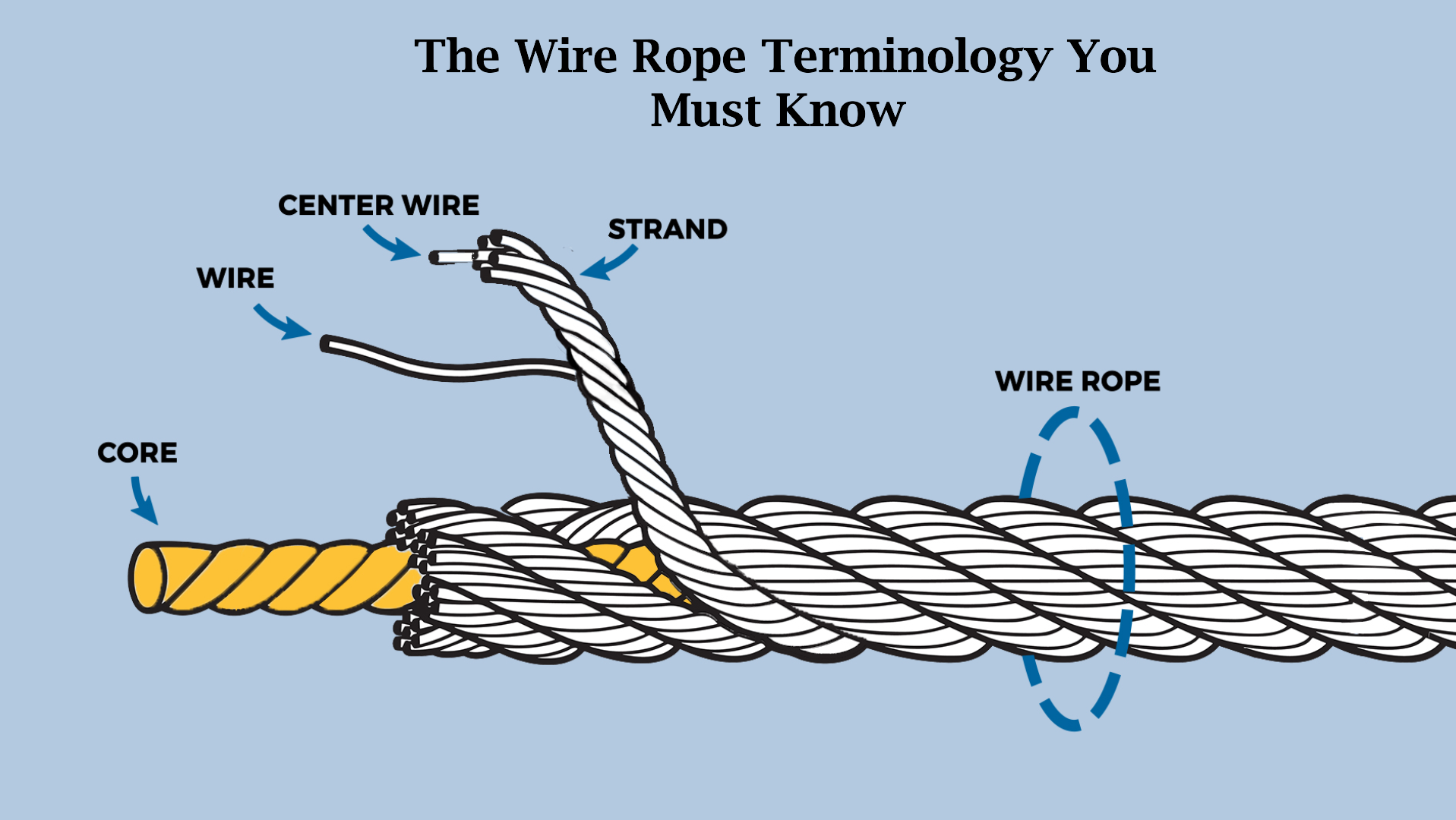

The weight of the loads being lifted and moved is carried by steel

wire ropes, which are the lifelines of cranes. The ropes are created by

twisting multiple strands of steel wires together in a helical pattern. Crane

operations rely on their strength, flexibility, and durability. Selectio

How are steel wire ropes used in cranes?

The application of steel wire ropesin cranes helps to

load, lift, lower and transport heavy objects. Different types of cranes are

majorly used in construction sites, harbors, etc. Steel wire ropes are used in

the cranes for lifting and hoisting purposes. These steel wire ropes are

attached to a crane at one end and fitted to a hook or a swivel at the other

end that carries a load. The steel wire ropes help in transporting the load in

a controlled manner.

Steel wire ropes make the process of

lifting and lowering heavier objects smooth and easy. Due to the high tensile, strength, and

flexibility of the steel wire ropes, their usage in crane application is

imperative. The radial elastic rope structure absorbs dynamic force easily and

allows heavy objects to be carried and moved with ease.

Steel wire ropes like galvanized wire ropes, stainless steel, and high-carbon steel wires are used in cranes. Among them, galvanized steel wire ropes are mostly used.

Why are steel wire ropes used in cranes?

Before steel wire ropes were

invented, chains were used to lift and transport heavy objects. However, the

arrangement of chains was linear, and even if one chain link fails the whole

system fails. Due to this inherent disadvantage, experts discovered the idea of

steel wire ropes which are parallel arrangements of load-bearing elements. Even

if one rope element fails, the breaking strength of the wire rope is reduced

only locally which helps the entire system continue working without fail.

Steel wire ropes are multiple

redundant systems which means they are made up of multiple strands of wire

ropes and thus even if one wire rope fails or breaks there are multiple other

ropes to carry the load.

BWR manufactures high quality steel

wire ropes for various crane applications. From non-rotating 19 strand & 35

strand ropes to special 8 stranded ropes. We also offer compacted ropes &

ropes with cushion core or plastic covered cores.

Learn more about our products, company & our

journey of excellence by visiting our website: https://bharatwireropes.com/

For all questions or

inquiries from India email us on domestic@bharatwireropes.com

For all questions or inquiries from

outside India email us on exports@bharatwireropes.com

You can also get in touch with us by

messaging us on LinkedIn- https://www.linkedin.com/company/bharatwireropes