Earth Wire - 1x7

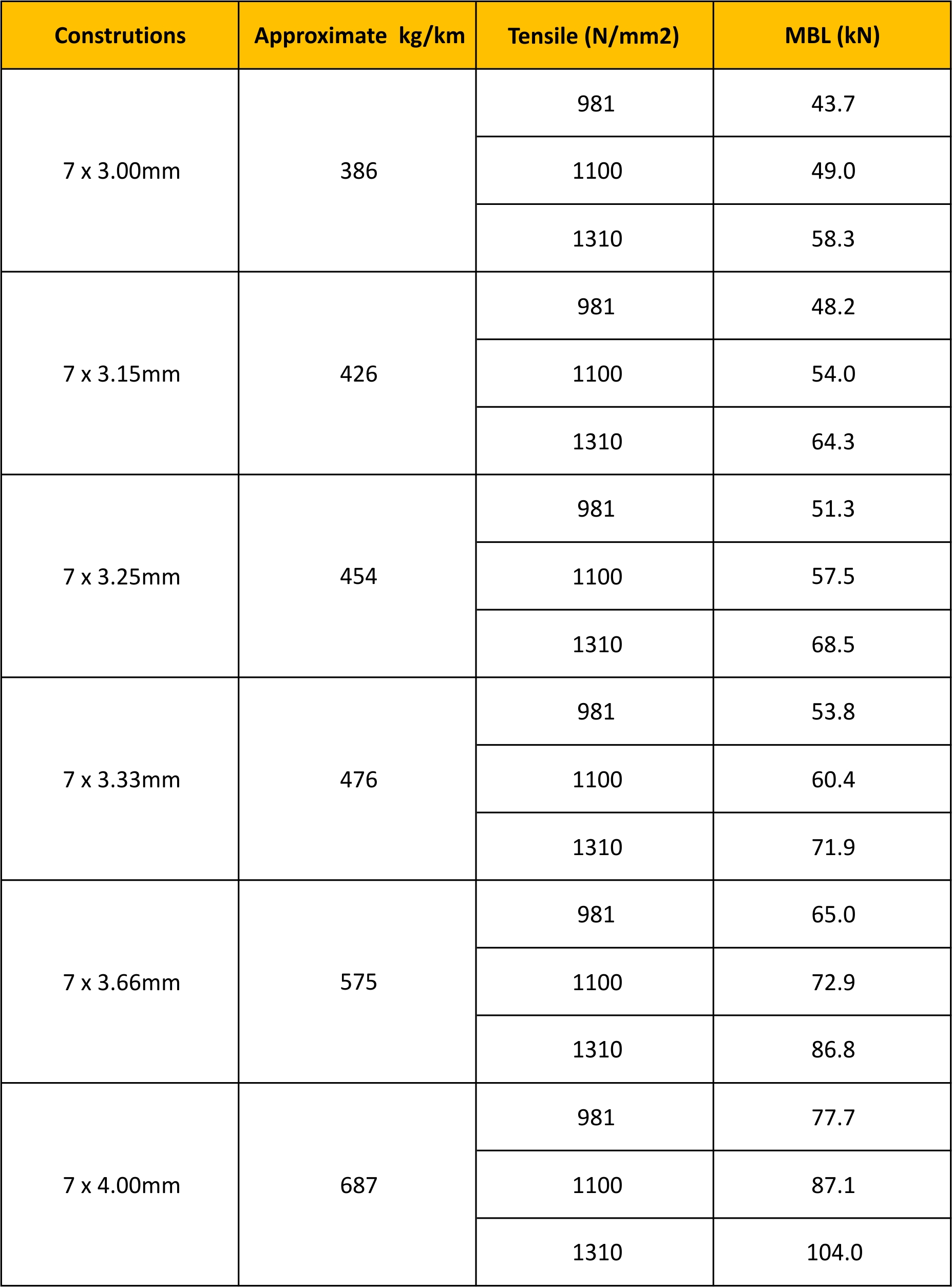

Applications

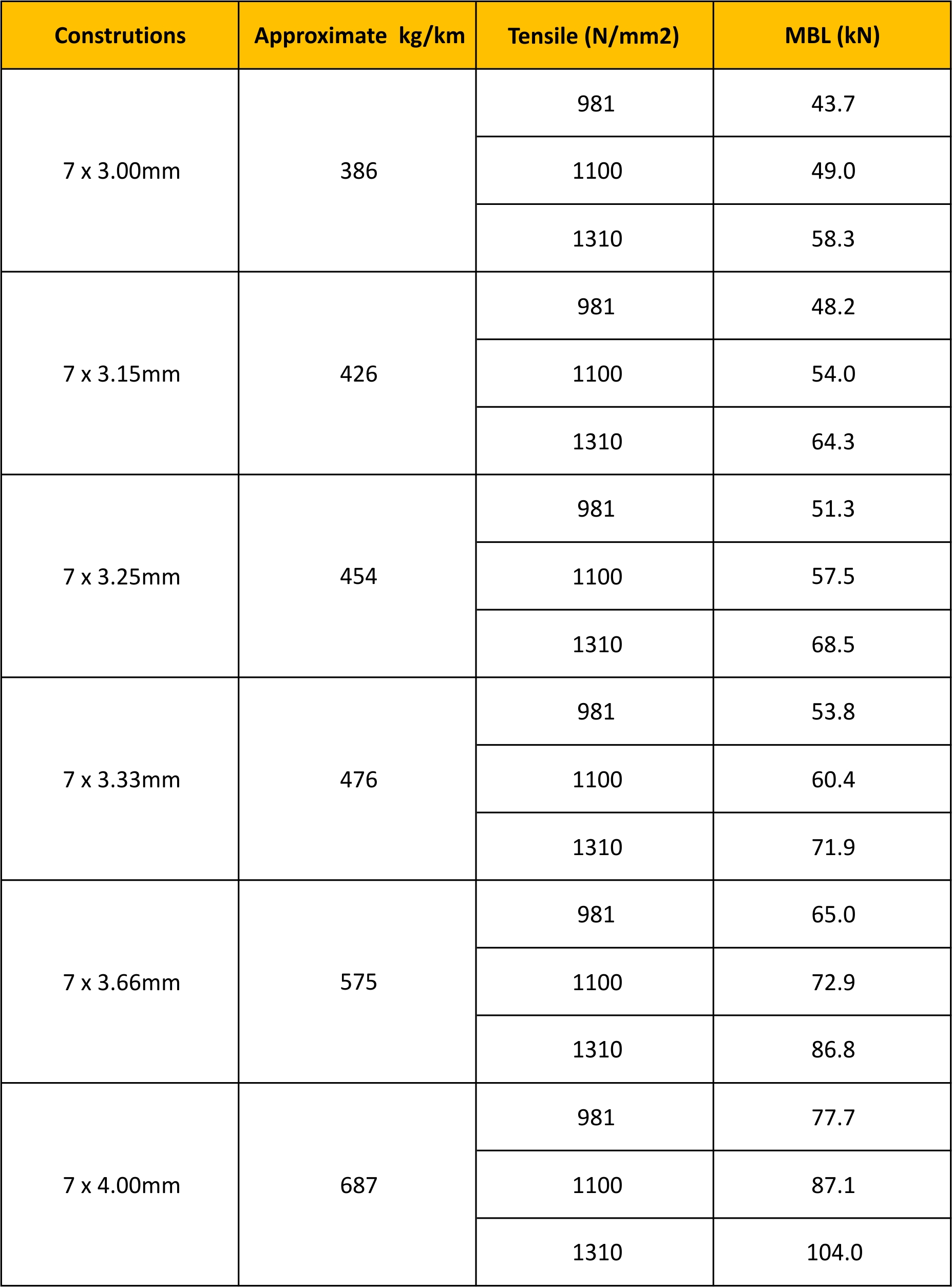

Specifications (USP)

- IS 12776

- IS 2141 and as per customer's specification.

Available In

- RH (Right Hand Lay)

- LH (Left Hand Lay)

Finish

- Bright

- Galvanized

Earth Wire is used as the medium to transfer the leakage of current if any from metallic body to the earth to prevent the shock. Earthwire for Overhead Power Transmission lines, Core Strands for Overhead Power Transmission Conductors.